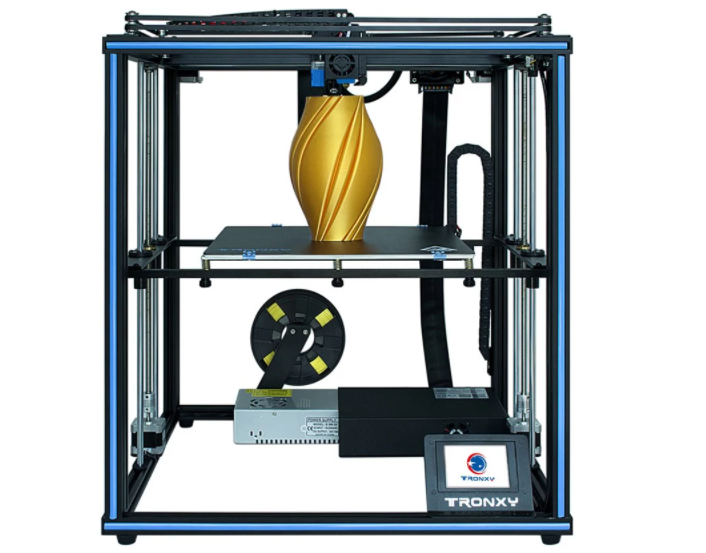

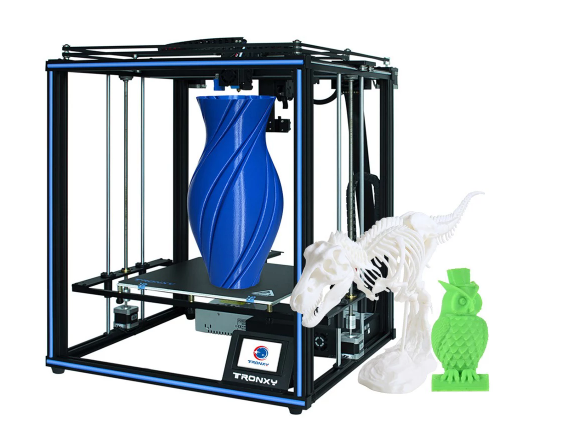

The working principle of a 3D printer is to first design a complete three-dimensional model (also known as computer-aided design) on the computer, then load the “printing materials” such as colloid or powder into the printer, and then connect the printer to the computer. The “printing material” and the three-dimensional model are superimposed layer by layer through computer control, and finally, the blueprint on the computer is turned into a real object. This 3D printing technology that creates three-dimensional objects through continuous physical layers is a form of additive manufacturing process. Compared with traditional additive manufacturing processes, it has the advantages of fast speed and low price. The printing device software running on the Windows network or workstation can read most of the 3D file format computer-aided design drawing data. The function of this kind of software is to transmit data to the 3D printing device, thereby controlling the movement of the print head and the output of materials. When the 3D printing equipment is working, the plastic model material filaments and the soluble support material will be heated to a semi-liquid state, and then output through the extrusion head to accurately deposit into extremely fine layers. The layer thickness ranges from 0.005 inches to 0.013 inches (that is, 0.127 mm to 0.33 mm), and the specific value depends on the performance of the printing device. For example, the model printed by TRONXY X5SA PRO 3D Printer generally has a thickness of 100 microns-400 microns, that is, 0.1 mm-0.4 mm.

To summarize briefly, the 3D printing process is essentially 2D (two-dimensional) printing, but it needs to be printed over and over again on the basis of 2D printing, layer by layer until a 3D product is finally formed. The use of 3D printing requires modeling and slicing first, and finally to a 3D printer to complete the printing work.

Specific steps:

1. Assemble and level the 3D printer. If you buy a new printer, you must first assemble and level the printer device. Some printers are entry-level and the assembly is very simple. It only takes 2 steps and 5 minutes to complete the assembly. Some printers Transported to us in the form of scattered parts, it is a DIY-level printer. It takes longer to assemble, about 30 to 60 minutes.

2. To build a model, we can model with computer modeling software or download a model from a 3D printing-related website.

3. Copy the models to the 3D printer via SD card or USB flash drive. After printing settings, the printer can print them out. Some 3D printers also support WIFI connection printing.